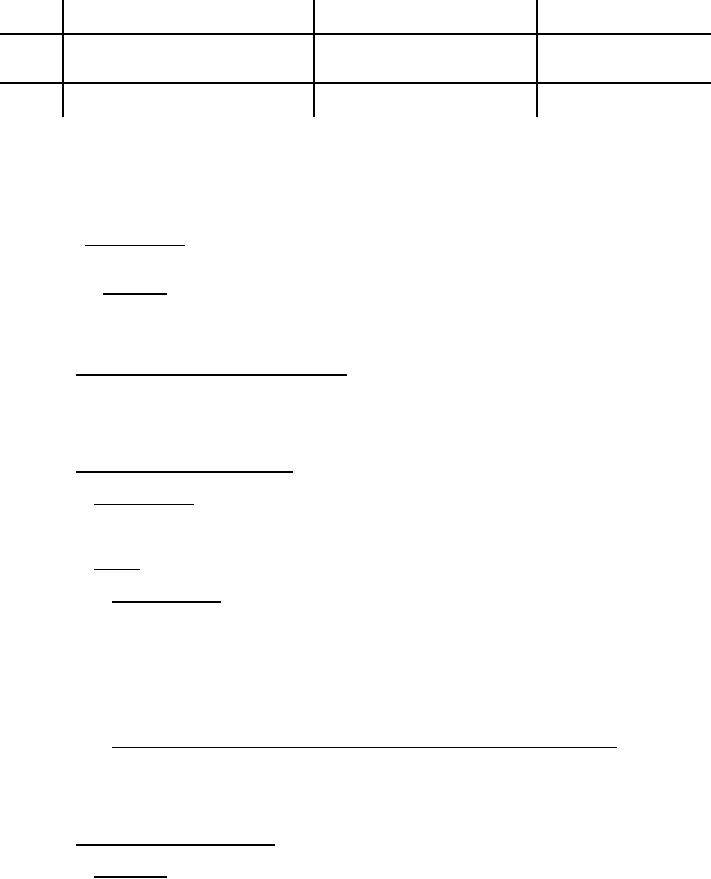

MIL-DTL-52872D

Item

Description

Identification

Quantity

No.

1

Stable base drawings of

13220E3220, sheets 2,

1 per sheet (see

processor printed wiring

3, and 4

note 1)

board (PWB)

2

Stable base drawings of

13220E3240, sheets 2

1 per sheet (see

transceiver (PWB)

and 3

note 2)

Notes:

1.

Provided only when complete UMSs, processors or processor CCAs are

procured.

2.

Provided only when complete UMSs, transceivers or transceiver CCAs

are procured.

3.11. Workmanship. Workmanship shall be in accordance with the guidelines

and guidance paragraphs of MIL-HDBK-454, guideline 9.

3.11.1.

Welding.

Sheet metal welding shall be in accordance with AWS

D9.1.

4.

VERIFICATION

4.1. Classification of inspections.

The inspection requirements specified

herein are classified as follows:

a.

First article inspection (see 4.2).

b.

Conformance inspection (see 4.3).

4.2.

First article inspection.

4.2.1. Examination. Each first article UMS and major components or

transducer kits when furnished separately shall be examined as specified in

4.4.1. Presence of one or more defects shall be cause for rejection.

4.2.2.

Tests.

4.2.2.1. Complete UMS. The complete UMS shall be subjected to the tests

marked "X" in column 1 of table II. Individual testing of major components of

the complete UMS is not required. Failure of any test shall be cause for

rejection. Unless otherwise specified (see 6.2), five UMSs shall be subjected

to environmental tests (see 4.4.2.5), twelve UMSs shall be subjected to the

reliability test (see 4.4.2.7) and, when required (see 6.2), one UMS, selected

from the environmental test units, shall be subjected to the electromagnetic

susceptibility test (see 4.4.2.6).

4.2.2.2. Major components or transducer kits furnished separately. Major

components or transducer kits furnished separately shall be subjected to the

tests marked "X" in column 1 of tables III through V. Failure of any test

shall be cause for rejection. Unless otherwise specified (see 6.2), five

units shall be subjected to each test.

4.3.

Conformance inspection.

4.3.1. Sampling. Sampling for tests shall be in accordance with

ANSI/ASQC-Z1.4. Sample size shall be determined by using tables I and IIA,

special inspection level S-2. A lot shall be accepted when no defects are

found and rejected when one or more defects are found. Samples shall be

randomly selected from production lots.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business